*45 tons of pressure

*Programmable NC controller

*9.84” stroke length

*220V 3-phase power

*36″ working table height

Features:

Electronic encoders make this hydraulic press brake accurate to +/- .002”

Control the bending stroke with 2 buttons or with the foot pedal, so your hands are free to guide the material. Numerical control (NC) programmer can store up to 50 programs with 10 bends per program

You can adjust the pressure of the hydraulics for your material. You can also run the metal press brake in a manual mode for one-off projects as well as set-up

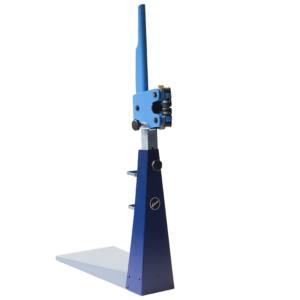

Robust manual back gauge bolts to the machine and helps with repeatability and product counter makes production runs more efficient

Machined table, 36” high, keeps your material perfectly level. No need to hold one side and hope it’s lined up!

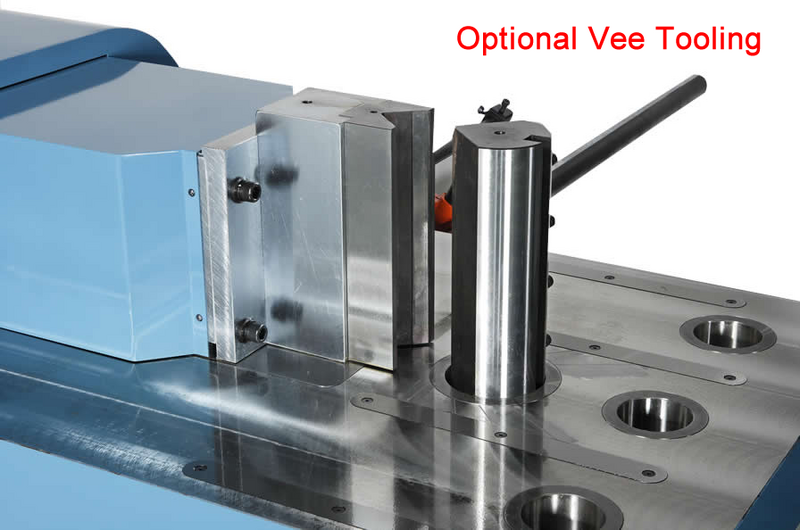

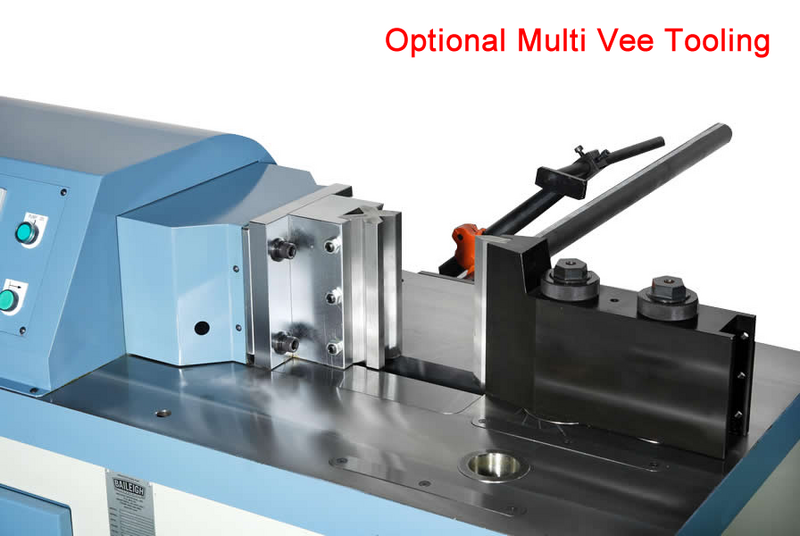

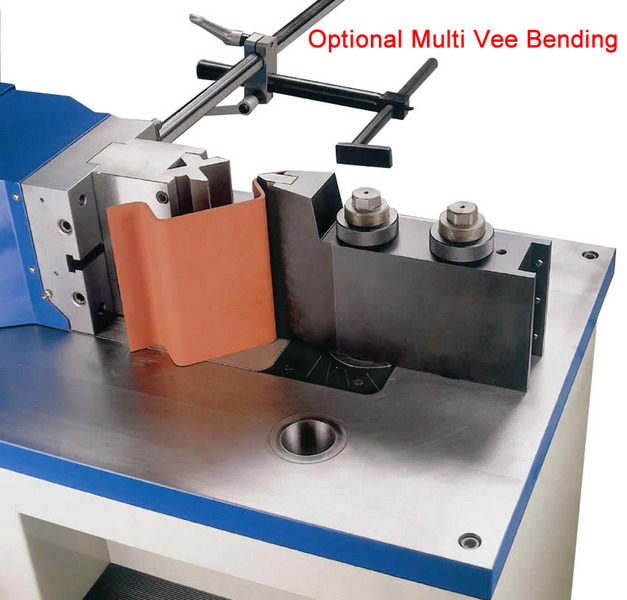

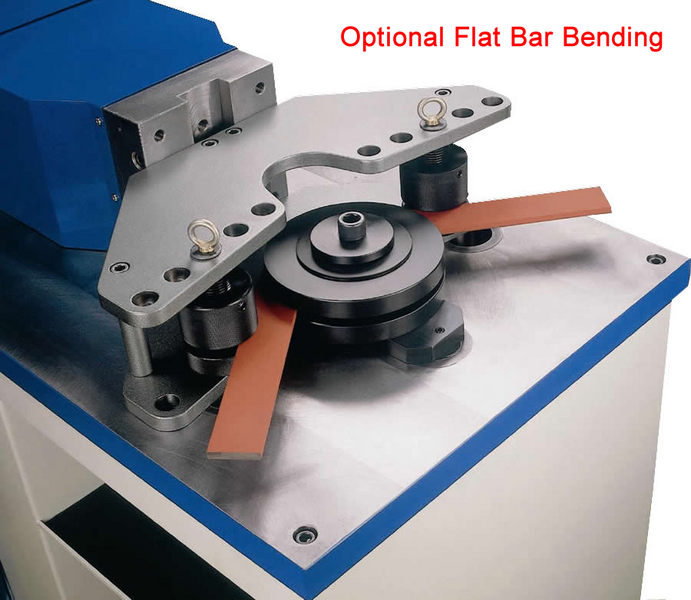

Quick-release tooling system makes changes fast and simple. Just turn the handle and the post will lift. The V die slides in and out

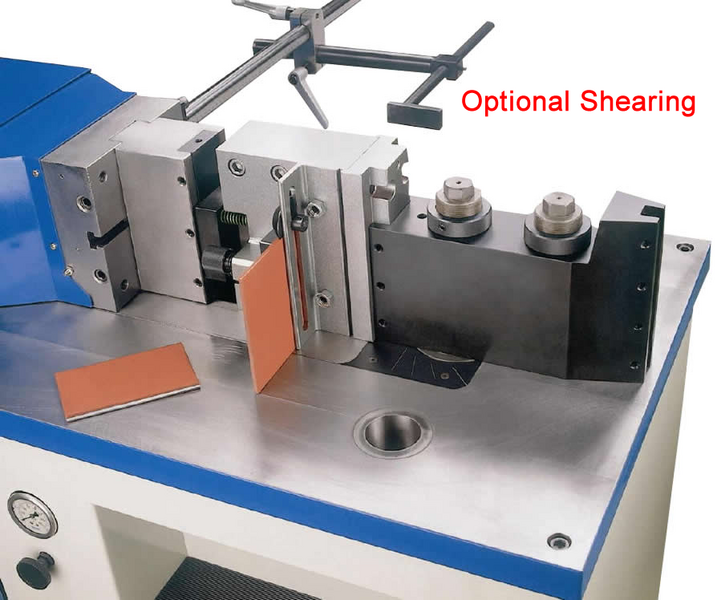

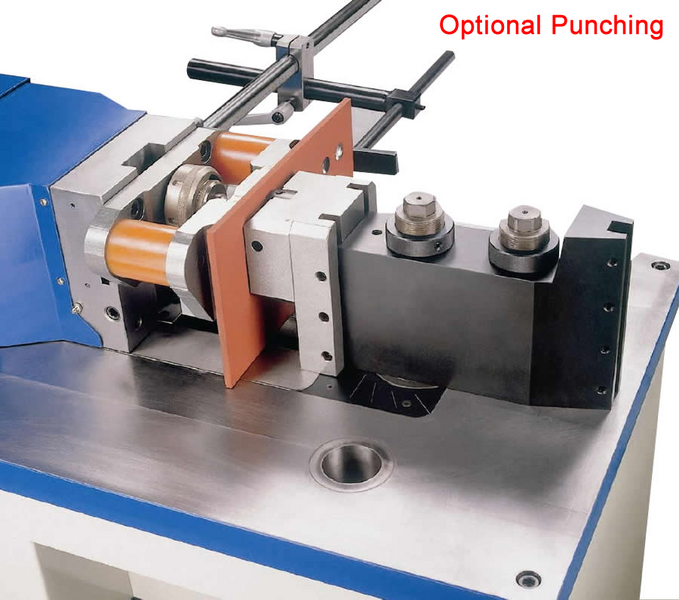

Includes 80mm single-V tooling (V-opening die and V post). Also accepts attachments for punching, straightening, shearing, and even pipe bending

Many additional tooling sets are available. We can find the right one for your project or create a custom set, if necessary

2,266-pound steel frame, made from 4 powerful pieces of inch-thick flat bar, will keep results accurate for many years and won’t flinch under pressure

Industrial-grade hydraulic system is located on top of the metal press brake to reduce flex and shelving in the front can hold tooling and items you might need on a daily basis

About Baileigh Industrial

At Baileigh Industrial®, we design and manufacture industrial metalworking and woodworking machinery that delivers reliable, precise results over decades of use. Since 1999, Baileigh has taken pride in earning a reputation for innovation and customer satisfaction.