Features:

Massive 20 hp motor runs on 480-volt 3-phase power with 1” mild steel maximum capacity and 120” (10-foot) length

All 4 forming rolls are hardened and polished with 2 central driven rolls

Dual hydraulic motors and high-efficiency planetary gearboxes directly rotate the 2 driven rolls

Front rolls have independent hydraulic lifters that go in the orbital pattern and stabilizer torsion bar system keeps front rolls parallel to the top roll

Fast and easy to use: Pinch the plate between the 2 central driven rolls, pre-bend the leading edge, and roll the body of the part along with the trailing edge all in one direction and in one pass

Plate is always pinched during the rolling cycle, so there’s no chance to lose the position

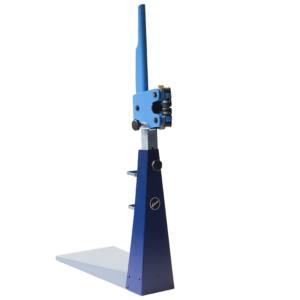

Conveniently movable operator console with control panel with toggles on the console that make it simple to control the roll movement

2 DROs on the control panel show the front and back roll positions for repeatability

Hydraulic system for material removal: yoke on top roll drops, allowing the roll to lift

Fully integrated steel plate frame helps maintain accuracy and prevent distortion or flex and includes conical bending system

About Baileigh Industrial

At Baileigh Industrial®, we design and manufacture industrial metalworking and woodworking machinery that delivers reliable, precise results over decades of use. Since 1999, Baileigh has taken pride in earning a reputation for innovation and customer satisfaction.