Eckold KF 170 PD Kraftformer

The pneumatic powered Eckold KF 170 PD is the most versatile of the Kraftformer models. The machine can be switched between single and continuous stroke and is therefore ideal for corrections and adjustments. Because of the single stroke option, tooling inserts are available for clinching, punching, notching and more. The Eckold KF 170 PD can easily handle materials up to 14 gauge (.078″ / 2 mm) mild steel.

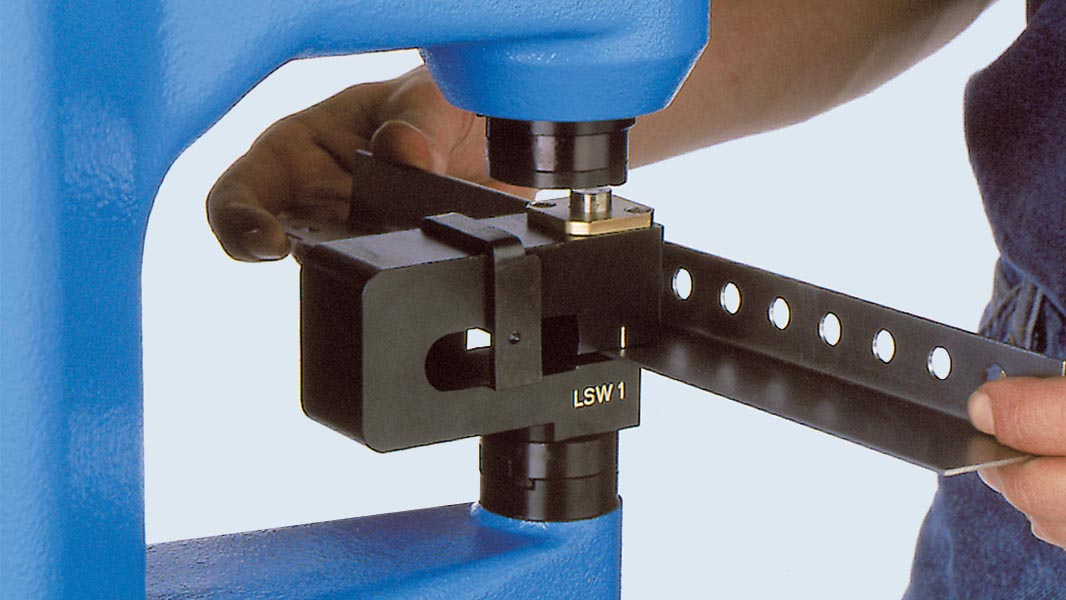

The KF 170 PD is air driven and released by a foot pedal, either in single or continuous stroke mode. The single stroke function is especially useful for correction jobs. In continuous mode, the KF 170 PD allows for fast and easy forming. The machine is adjustable in height, allowing the operator an ergonomic working position. As with all of the other Kraftformer models, the vast number of tooling available makes the KF 170 PD the perfect machine for professional metal shapers. Tooling options are available for shrinking, stretching, doming, planishing, flattening, straightening and more. The forming tools have a quick-change design which helps eliminates down time.

Eckold KF 170 PD Kraftformer Features:

- Easy mobility around the shop

- Single and continuous stroke modes

- Precision setting of forming forces

- A variety of tooling inserts for different materials and forming operations

Eckold has been a leader of shrinking and stretching technology since 1957 because they offer an unrivaled range of solutions. These machines have been an industry favorite in sheet metal forming or finishing work because they’re precise, durable, and easy-to-use. When sheet metal needs to be shaped and profiles must be bent, Eckold is your industry leader.

Contact us today to start your quote!

Please complete the form below or call us at (815) 451-7086.

- Tooling not included

- Lead times may vary, please contact us for exact availability