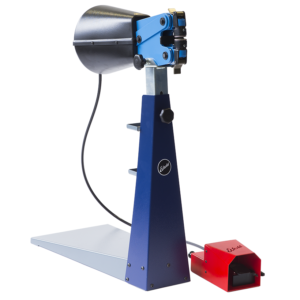

Stefa VHX Up/Down Long Folder

Standard Features

- Max Capacities

- 14 ga. (2mm) Mild Steel

- 0.12″ (3mm) Aluminum

- 18 ga. (1.25mm) Stainless

- Back gauge Range (max-min): 35″<-> 0.2″ (900mm <-> 5mm)

- Servo Motor Back gauge tolerance: -0.01/+0.02mm

- No of Grippers: 6-8 (depending on machine length

- Servomotor back gauge: 98″/ s (250mm/s)

- Opening height clamping beam: 13.8″ (350mm)

- Max rotation of bending beams: 135°

- Speed of bending beams: 90°/s

- Bending tolerance: +/- 0.5°

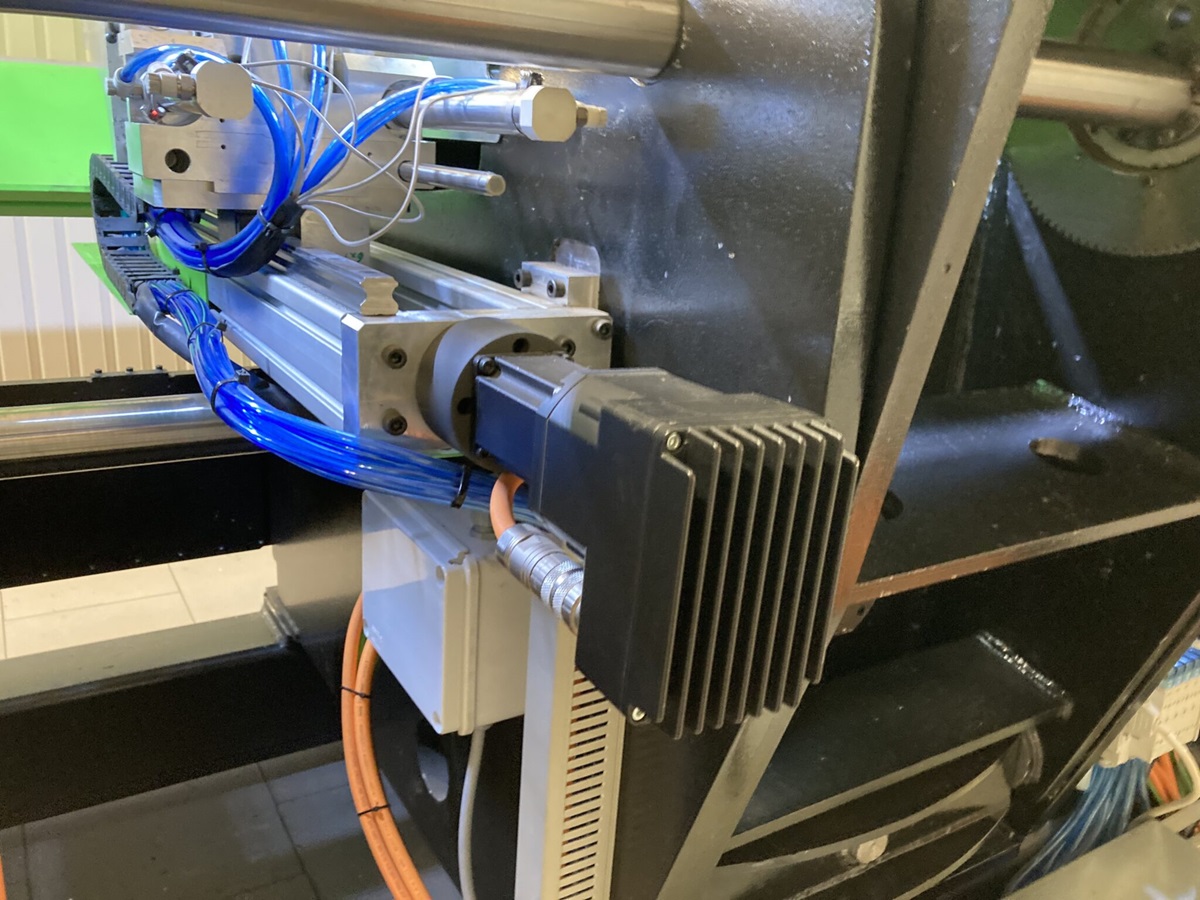

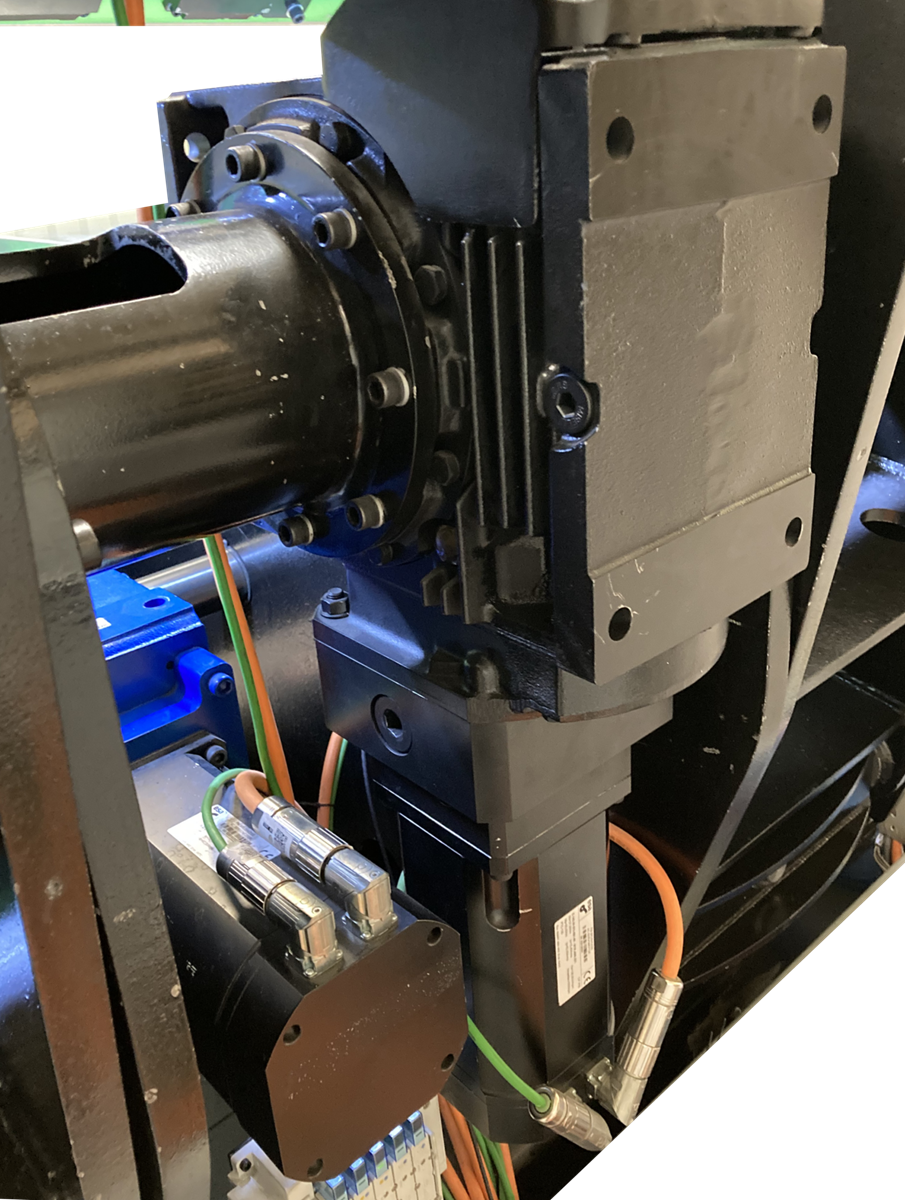

Electrically Driven Axes

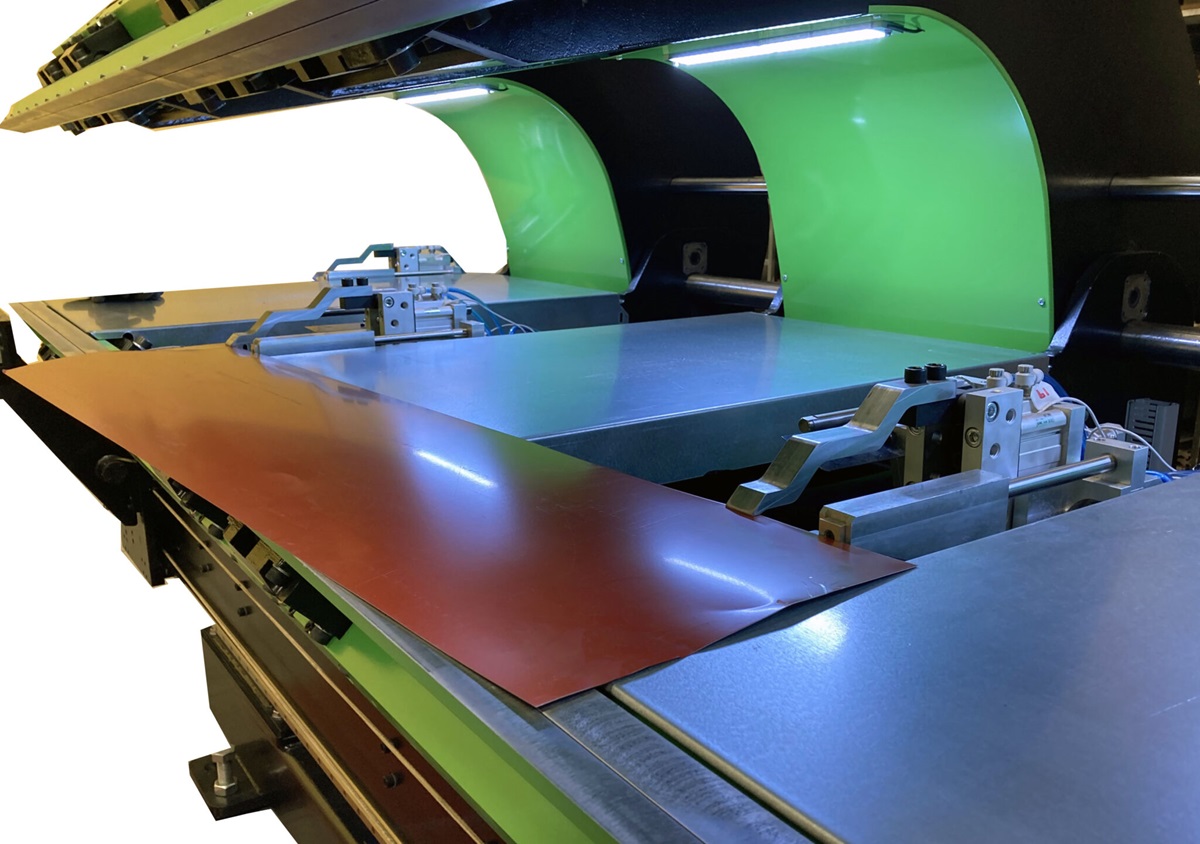

Introducing the latest breakthrough in CNC metal folding technology, the Stefa VHX Hydra-Electric CNC Up-Down Folder. This innovative machine marks a significant milestone in the roofing industry, addressing a longstanding need that roofers have been eagerly anticipating. With its cutting-edge design and advanced electric capabilities, the Stefa VHX streamlines the metal folding process like never before. Roofers can now achieve unparalleled precision and efficiency, making their jobs easier and more efficient than ever. Say goodbye to traditional methods and welcome the future of metal folding with the Stefa VHX Hydra-Electric CNC Up-Down Folder.Speed and Positioning Precision

Speed and precision are paramount in the performance of the Stefa VHX. Through careful selection of the optimal combination of screw lead and motor rotational speed, this machine achieves remarkable velocity. In fact, its bending beams are capable of rotating a full 90 degrees in just one second, demonstrating its impressive speed capabilities.

One notable advantage of this machine is its ability to operate without the need for warm-up time. This feature significantly enhances productivity, as operators can get to work immediately, further solidifying the Stefa VHX’s position as a cutting-edge solution in the world of metal folding technology.

PerfectBending/Hemming Every Time

Achieving perfect bending and hemming is made effortless with the Stefa VHX. Thanks to the individual drive capabilities of its clamping arms, precise positioning of each clamp arm becomes a reality. This unique feature allows for individual adjustment of the height of the edges in an open hem, effectively eliminating the challenges typically associated with this process.

The Stefa VHX offers the flexibility to correct any angle deflection in the material by fine-tuning the pressure applied to each clamp. This capability enables operators to make precise angle corrections, ensuring that the final product is flawlessly bent and meets the desired specifications. With these advanced features, the Stefa VHX empowers users to consistently achieve perfect bends and hems, setting a new standard for precision in metal folding technology.

Positive and Negative Bending

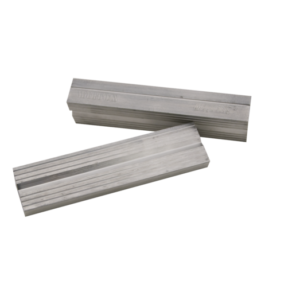

With an impressive 270 degrees of flexibility, the Stefa VHX introduces a game-changing approach to sheet metal folding. Its ability to perform both positive and negative bending opens up new avenues for productivity in the industry. This innovative feature not only accelerates the production process but also reduces the time required to manipulate the material. The bending beams of the Stefa VEX come equipped with reinforced tools that can be easily replaced in the event of damage. This ensures minimal downtime and maintenance costs, keeping the machine running smoothly and efficiently. In summary, the Stefa VHX’s unparalleled flexibility and adaptability make it a standout choice for those seeking enhanced productivity and convenience in sheet metal folding operations.

Automatic Bending

The Stefa VHX redefines efficiency with its operator-free capabilities. Its advanced gripper can securely hold the material in place, while automatic positioning takes care of the rest. In most cases, there’s no need for an operator to handle the sheet metal, streamlining the entire process. The gripper’s dual backstops, located at the edge and the rear, enable precise folding with sides at 90 degrees, accommodating materials up to 45mm in height. However, for those situations where more traditional methods are preferred, the option to work with a normal backstop for semi-automatic operation is also available, providing users with the flexibility to choose the most suitable approach for their specific needs. This adaptability makes the Stefa VHX a versatile and user-friendly solution in the world of sheet metal folding.

Safety

Safety is paramount with the Stefa VHX double folder. To ensure the well-being of operators and prevent accidents, the machine is equipped with comprehensive protective measures. Physical fences surround the machine, creating a secure barrier.

In automatic production mode, safety lasers are employed to meticulously monitor the danger zone, preventing any unauthorized access while the machine is in operation. Additionally, when the machine operates in semi-automatic mode, individual lasers are strategically placed to safeguard fingers and hands in the clamping beam and shear danger areas. This added layer of protection allows operators to work confidently using pedals, maintaining a safe and efficient working environment throughout various operational modes. The Stefa VEX prioritizes the safety of both operators and the production process itself.