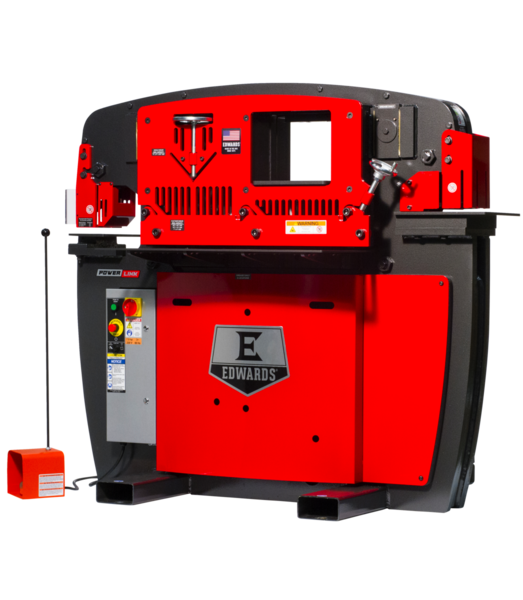

Features:

Adjustable electric stoke control

Angle Shear blades have 2 corner radii for both thin and thick material and are made of precision tool steel with 2 cutting edges for extended life

ANSI B11.5-1988(02) Compliant Guarding

ETL Certified Controls

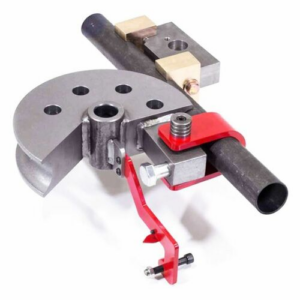

Five Workstations: Standard (4) – Punch, Flat Bar Shear, Angle Shear, and Coper Notcher. Open Cavity (1): Customize your ironworker with four optional attachments including Brake, Rod Shear, Multi-Shear, and Pipe Notcher

Flat Bar Shear blades are made of precision machined, high-quality tool steel with 4 cutting edges for extended life

Integrated Lock-out/Tag-out system with multiple location E-Stop (foot pedal & control panel) for added safety

Optimized workstation heights for improved efficiency

Punches are easily changeable, long-lasting and available from 1/8″ to 4″ diameters along with square, oblong, hex, metric, and custom shapes

Vertical movement produces even pressure resulting in precise punching and shearing with minimal distortion that results in extended tooling life

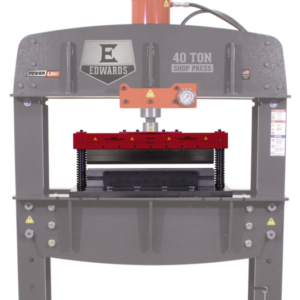

About Edwards

Today Edwards Manufacturing is primarily driven by its production of Ironworkers. The JAWS line of Edwards Ironworkers has recently been expanded with the addition of the new Edwards ELITE line. Edwards ELITE Ironworkers boast high-quality design and a host of integrated features. Both lines of Ironworkers are bolstered by our extensive line of Tooling Accessories, giving the user the ability to tailor their Ironworker to their specific needs. The Ironworker line is further complemented by a line of innovative Hydraulic Accessory Tools, powered by an Edwards Ironworker or the Edwards Porta Power, a portable hydraulic power unit. These tools expand the abilities of your shop quickly and economically.